Micro Injection

DEMGY FrasneThese are precisions of the order of a few tens of microns that are required by the rise of microsystems and miniaturization, which takes over all sectors, including primarily medical but also aeronautics energy or the automobile.

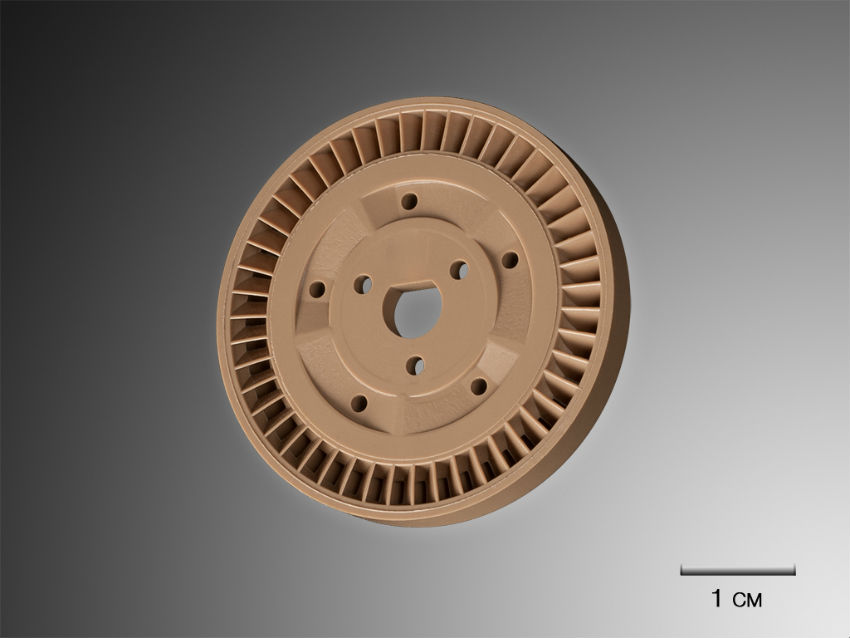

The production of technical parts of smaller and smaller size has been accompanied by the growth of injection of thermoplastic materials in micro-molds. This technology responds to the name of microinjection and requires a very sharp know-how, to bring the quality of treatment (tolerance, aspect decrease in weight, energy consumption, productivity ...) necessary for very small parts.

Micro injection, the necessary high performance

The DEMGY is able to implement very high precision plastic injection technologies, completing its high-value, high-performance composite and polymer transformer offering.

The Group has 22 Arburg presses between 15 and 100 T. The control of the injection parameters is carried out continuously for increased quality, possibly by means of sensors placed in the cavities.

.jpg?1559665112672)

The lines are all equipped with 3 or 6-axis robots to provide camera control, possible recovery operations and room conditioning. Injection in controlled atmosphere ISO 7 or 8 is particularly suitable for medical applications, but also electrical or automotive.

A confirmed experience

We have a proven experience for the injection of thermoplastics (Peek, PPS, LCP, PEI, PPSU, POM, etc ...) and thermosetting (phenolic). Special expertise is required to design the molds for the loaded materials (glass / carbon fibers, glass beads, mineral, PTFE).

Micro-injection expertise: DEMGY Frasne redefines ecological standards with KITPIC®

Dive into the heart of ecological commitment with our DEMGY Frasne site, specialists in precision micro-injection in the medical sector.

Their recent collaboration with Allerclear has given rise to KITPIC®, an innovative lancet dedicated to allergological testing. Keen to comply with ecological standards, the customer expressed the wish for the product to be manufactured in France, favoring short circuits and minimizing the use of raw materials.

KITPIC® is a lancet based on a patent (currently being validated) that improves the efficacy and reproducibility of skin allergy tests known as "prick-tests". While competitors use steel or petroleum-based plastics, KITPIC® is made from Arkema's Rilsan®: a plant-based polymer derived from castor oil.

Because having a better material isn't enough, the new lancet uses 70% less material weight than commercially available plastic lancets. The primary packaging itself is made from a single material for greater recyclability, and the packaging is designed to enable recyclable waste to be collected by a consumer channel.

With its expertise in plastic micro-injection, DEMGY Frasne has succeeded in considerably reducing the weight by 70%. This feat was achieved by cleverly using a castor-oil-based biosourced resin, reinforcing the product's durability. In keeping with our ecological principles, the primary and secondary packaging (sachet and carton) are made from the same recyclable material, underlining our commitment to preserving the ecosystem.

On the technical side, the major challenge lay in the design of the lancet tip, requiring very superficial penetration of the patient's skin to guarantee reliable analyses.

Our team rose to this challenge with flying colors, demonstrating tooling and machining expertise in the field of precision micro-injection.

With our expertise in micro-injection technology and microfluidic part manufacturing, DEMGY positions itself as a key player in the high-precision industry dedicated to miniaturization and fluid flow optimization.