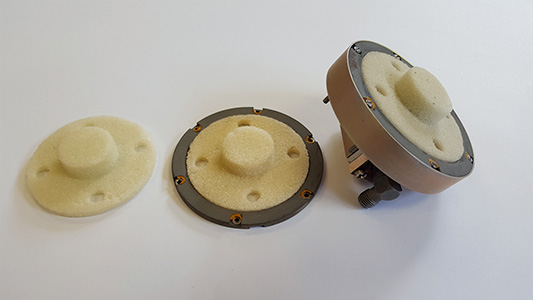

P10™ foam, electromagnetic wave absorber

P10™ foam has been marketed for over twenty years by DEMGY, which controls the entire process: from manufacturing to machining. P10™ foam makes it possible to fill a void inside a room, to reinforce it, without disturbing or altering the passage of electromagnetic waves. It is mainly used for Defense sectors.

.jpg?1560420171564)

Key benefits of P10™ foam

P10™ foam is a closed-cell rigid polyurethane foam.

These key features:

- Very good mechanical rigidity.

- Microwave transparency.

- High temperature behavior.

- Chemically stable.

These main applications:

- P10™ foam is generally used for the manufacture of radomes and antenna supports.

- Because of its excellent thermal and mechanical properties, P10 ™ foam can also be used for structural applications as a complex composite sandwich.

- For radio applications, the P10™ foam can also be impregnated in autoclaves with conductive fillers and becomes "MPU foam": see technical data in our catalog of microwave absorbers.

- P10™ foam is easy to metallize and can therefore become conductive on the surface. See the characteristics of our EMC metallization.

The physical properties of P10™ foam

- Which structure?

P10™ foam has a cellular structure of small cells. The P10™ foam can have inclusions up to 3 mm in diameter, with a limit of 10 inclusions per dm². - What is the apparent density?

Available grades (nominal apparent densities):

48 kg / m3, 128 kg / m3, 225 kg / m3, 380 kg / m3.

For each grade, the apparent density tolerance is +/- 15%.

N.B: Other grades can be manufactured on request. - What gross dimensions?

Available in any machined form and any size in blocks of 600x600x200 mm or 300 * 300 * 200mm.

Mechanical stress of P10™ foam.

The compressive stress at room temperature must not be less than the following values:

- Foam density 48 kg / m3: src> 0.5 MPa

- Grade 128 kg / m3: src> 1.3 MPa

- Grade 225 kg / m3: src> 3.5 MPa

- Grade 380 kg / m3: src> 15 MPa

Radio properties at f = 10 GHz

- Which measuring bench?

The dielectric constants "er" and dielectric losses "tan de" are controlled by a resonant cavity measurement at a frequency of 10 GHz using the vector network analyzer. - Detail of grade 48 kg / m3.

Dielectric constant "er" between 1.04 and 1.10.

Tangent of losses "tan of" <6.20x10-4. - Detail of grade 128 kg / m3.

Tangent of losses "tan of" <1.96x10-3 . - Detail of grade 225 kg / m3.

Dielectric constant between 1.25 and 1.36.

Tangent of tan losses of <2.82x10-3. - Detail of grade 380 kg / m3.

Dielectric constant between 1.40 and 1.73.

Tangent of tan losses of <3.90x10-3.

What traceability is put in place for P10™ foam?

- Traceability of the resin.

The preparation of the resin is made in a reactor adapted to the foam block sizes to be expanded. Each batch of resin manufactured has an index in the form of a letter incremented with each new manufacture. - Traceability of each foaming.

Each foaming carries an incremented letter for each new foaming campaign, and also refers to the batch of resin used.

Example: Lot of resin: D; foaming D / A on 28/05; Foaming D / B on June 20, etc ...

The declaration of conformity

Each delivery is accompanied by a declaration of conformity according to the NFL00-015 reference to the current index.