Gaining competitiveness through industrial robotics - DEMGY Atlantique

DEMGY Atlantique DEMGY Făgăraș DEMGY FranceWith nearly 5 million car key cases manufactured each year at its factory in Gétigné, DEMGY Atlantique proves that it is possible to combine economic competitiveness, technical excellence, and industrial sovereignty.

After 15 years of hybrid production between France and Romania, the company made the strategic decision to repatriate all production to France and set up a fully automated production line.

Background and challenges

Car keys are not just functional components: they embody the brand image of manufacturers and must combine dimensional accuracy with impeccable appearance.

Why change?

One of our clients in the automotive industry challenged us on three key points:

-

Reduce delivery times to support faster launches

-

Ensuring full traceability for each part, from molding to assembly

-

Increase flexibility to incorporate additional variants without extending cycles

To meet these expectations, we have chosen to bring production closer to the end market and adopt a fully automated production line in France.

This choice allows us today to offer:

- Enhanced responsiveness

- Quality controlled at 10–15 PPM

- A capacity of 140,000 pieces/week with more than 60 variants

The multi-site model remains a strength: we continue to offer solutions that combine our international sites when this meets our clients' objectives.

Phase 1 — An optimal process Atlantic ↔ Romania

Initially, DEMGY established a robust process between DEMGY Atlantique and its sites in Romania:

- Precision plastic injection molding

- Semi-automated assembly

- Quality control with Poka-Yoke systems

- Traceability via QR code

Initially designed as a semi-automated chain between France and Romania, production allowed for flexibility and volume.

|

|

Phase 2 — Relocation and full automation

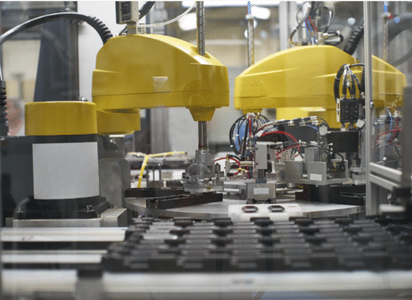

To meet new competitiveness requirements, DEMGY Atlantique has chosen to repatriate its entire production to Gétigné and has deployed a fully automated line:

- Workshop in 3x8

- Robotic assembly and automated inspections (vision, mechanical tests)

- Over 60 variations per key

- Objective: zero defects, full traceability, maximum responsiveness

|

|

Results achieved: 60 different models for 5 million cases produced annually

-

Quality: defect rate reduced to 10–15 PPM

-

Capacity: up to 140,000 pieces per week

-

Annual volume: nearly 5 million boxes

-

Competitiveness: local production with optimized costs

Territorial and human impacts

- 130 jobs at the Gétigné site

- Creation of an internal training center to train fitters, millers, adjusters, and automation engineers

- Promoting technical professions and developing local skills

|

|

Strategic vision

This project embodies a modern and sustainable French industry, capable of competing with Asian and Eastern European countries thanks to:

- Advanced automation

- Industrial robotics

- Operational excellence