DEMGY Atlantique

DEMGY Atlantique, située à Gétigné en .jpg?1643298359082) Loire-Atlantique, s’intègre dans un environnement industriel totalement impliqué dans la transformation des matières plastiques -pièces et outillages- et accompagne le développement de vos projets. Cette filiale est le Centre de Compétences “Automotive” (automobile) du Groupe, et coopère également avec des entreprises des secteurs de l’Aéronautique, de la Bagagerie ou encore du Médical.

Loire-Atlantique, s’intègre dans un environnement industriel totalement impliqué dans la transformation des matières plastiques -pièces et outillages- et accompagne le développement de vos projets. Cette filiale est le Centre de Compétences “Automotive” (automobile) du Groupe, et coopère également avec des entreprises des secteurs de l’Aéronautique, de la Bagagerie ou encore du Médical.

Notre cœur de métier se concentre principalement sur l’injection, l’assemblage et le formage. Notre concept Multiplasturgy® nous permet également de vous offrir des projets personnalisés grâce à des technologies tels que l’usinage, la métallisation et la peinture. Nous nous impliquons pour mener à bien tous vos projets, notamment pour la production en grande série de pièces et sous-ensembles.

Notre plus grand atout ? La maîtrise de nos savoir-faire. En matière de gestion de projet, notre organisation nous permet, grâce à la complexité et à la précision de nos outillages, de fabriquer des pièces répondant à vos besoins spécifiques avec pour objectif l’optimisation de notre réponse à vos cahiers des charges, même les plus exigeants. Nos ateliers de production répondent aux exigences qualitatives - techniques et logistiques - pendant toute la durée de vie de vos projets.

Découvrez nos expertises et nos technologies

La principale force de DEMGY Atlantique est la maîtrise de la production en grande série de projets complexes et multi technologiques. Notre expertise vous assure une maîtrise complète des procédés de transformation, afin de vous garantir une qualité irréprochable pour vos produits finis. De nombreuses technologies sont utilisées pour produire vos pièces techniques ou d’aspect.

Outillage, injection & valeur ajoutée

DEMGY Atlantique, c’est avant tout une gestion optimale de l’outillage, celui-ci est conçu en interne, grâce au savoir-faire de nos équipes dotées d’outils digitaux 4.0. Notre atelier de fabrication d’outillages permet de vous garantir l’ajustage, l’amélioration et l’entretien tout au long de la vie de vos pièces.

Nous mettons en œuvre différentes technologies comme l’injection bi-matière, le surmoulage et l’injection gaz. La première permet d’injecter plusieurs matières aux caractéristiques différentes sur une même pièce telles que la couleur, la rigidité ou une compatibilité différente à la métallisation, etc ...  La seconde, quant à elle, permet d’intégrer une fonction métallique sur une pièce plastique en surmoulant un insert. L’injection gaz fonctionnalise les pièces plastiques en intégrant une veine de gaz qui améliore la stabilité dimensionnelle : limiter les déformations et réduire certaines épaisseurs. Ces technologies peuvent intégrer la pose, manuelle ou automatique, d’inserts plastiques ou métalliques. Dans le domaine du surmoulage, chaque équipement est spécifique et fonction des quantitatifs, avec ou non une automatisation et une robotisation.

La seconde, quant à elle, permet d’intégrer une fonction métallique sur une pièce plastique en surmoulant un insert. L’injection gaz fonctionnalise les pièces plastiques en intégrant une veine de gaz qui améliore la stabilité dimensionnelle : limiter les déformations et réduire certaines épaisseurs. Ces technologies peuvent intégrer la pose, manuelle ou automatique, d’inserts plastiques ou métalliques. Dans le domaine du surmoulage, chaque équipement est spécifique et fonction des quantitatifs, avec ou non une automatisation et une robotisation.

Notre expertise technique répond aux fortes exigences dimensionnelles et qualité notamment sur vos pièces de sécurité, telles que les raccords essence ou encore des éléments d’airbags.

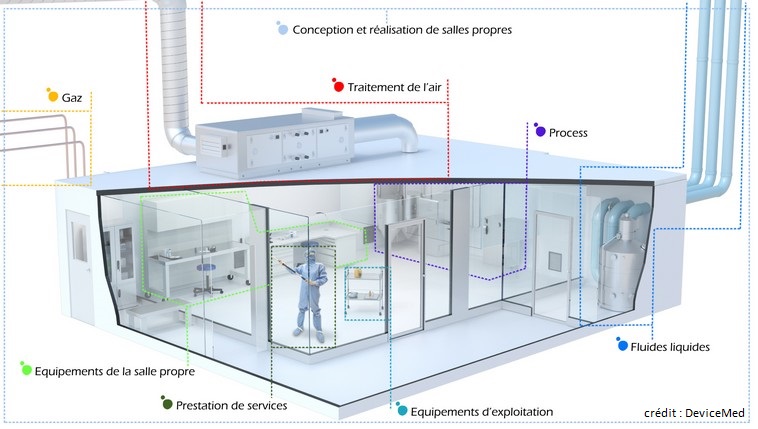

Nous vous offrons aussi la possibilité d’injecter vos pièces en environnement contrôlé afin de maîtriser le niveau de propreté de celles-ci, afin de se prémunir du risque de toutes pollutions dues aux particules volatiles de petite taille. Nous répondons ainsi aux exigences de plus en plus sévères du monde de l’électronique, des semi-conducteurs et de tout objet connecté.

Nos savoir-faire donnent l’aspect et l’esthétisme que vous souhaitez à vos pièces grâce à nos technologies. DEMGY Atlantique peut sérigraphier, tampographier ou bien marquer à chaud vos produits. Nous pouvons également peindre ou chromer pour un aspect plus esthétique ou assurer une fonction conductrice.

Enfin, grâce à la technologie Roctool®, nous pouvons embellir et améliorer l’état de surface d’une pièce injectée grâce à un générateur à induction. Un avantage complémentaire à la technologie Roctool®, est la possibilité de magnifier la surface d’une pièce produite à partir de matière régénérée.

DEMGY Atlantique peut opérer un “in-mould labelling” (étiquetage dans le moule). Cette action consiste à poser un film sur la pièce qui résistera à la rayure, il personnalise également votre pièce avec votre logo par exemple. Votre décor fera partie intégrante de votre produit.

De même, si vous souhaitez effectuer une véritable métallisation sur vos produits, DEMGY Atlantique est en mesure de vous proposer des blindages électromagnétiques grâce à un revêtement PVD (dépôt physique en phase vapeur), en partenariat avec la société HEF.

Assemblage après injection et parachèvement

En tant que fabricant de pièces plastiques en grande série, nous vous proposons un complément aval de prestation : industrialisation des process d’assemblage. C’est le parachèvement ! Nous utilisons des technologies maîtrisées pour mener à bien vos projets. Nous pouvons effectuer et combiner le soudage, le clipsage, le bouterollage et le rivetage de vos produits. Le procédé de bouterollage permet de donner la forme souhaitée à vos rivets pour qu’ils s’intègrent parfaitement dans vos ensembles.

DEMGY Atlantique est en mesure de réaliser de la soudure miroir ou ultrasons. Cette dernière permet d’assembler vos produits grâce à la chaleur générée par l’émission d’ultrasons. La soudure miroir, quant à elle, utilise une lame chauffante qui va assembler deux ensembles en un seul grâce à l’atteinte du point de fusion.

Composites thermoplastiques

Les composites thermoplastiques rendent accessibles les résines techniques (dont des biosourcées comme le PLA et certains polyamides) et leur renfort (fibres de carbone, de lin, de verre…) au monde de la grande série grâce à leur temps de transformation court et l’introduction de la juste quantité de matière.

Les composites thermoplastiques répondent aux enjeux d’allègement de nos clients ainsi que de nombreux secteurs d’activité (aéronautique, automobile, loisirs...).

Notre Atelier composites thermoplastiques permet de produire des pièces à formes complexes grâce à une large gamme de presses d’estampage et de thermocompression.

Liberté de création, liberté des formes : le composite thermoplastique sait s’adapter à l’hyperpersonnalisation.

Nos composites thermoplastiques garantissent des pièces résistantes aux chocs et reconnues pour leur légèreté, notamment dans les domaines de la bagagerie ou encore de la mobilité.

Notre ligne d’estampage est qualifiée par Airbus, spécifiée AIPI (Airbus Process Instruction) et AIPS (Airbus Process Specification), pour du PEEK/C, PPS/C. Pour les tester, nous utilisons des moyens de contrôle ultrasons (CND) également qualifiés par Airbus.

Un centre de recherche et de développement dédié aux composites thermoplastiques :

Une équipe pluridisciplinaire spécialisée en composites thermoplastiques managée par Ophélie Westphal, PHD en composites, met son expertise à votre service. Depuis le choix de la matière jusqu’à la transformation de matériaux, en innovant avec des procédés de production sur-mesure (dont le Netshape ou l’utilisation du système de chauffe par induction Roctool®), nous vous accompagnons dans le développement de vos applications, même les plus complexes.

Nos équipes de Recherche & Développement sauront vous développer des procédés spécifiques de production.

Pour en savoir plus, n’hésitez pas à contacter nos experts !

Nos composites thermoplastiques sont conçus pour une utilisation longue durée et sont recyclables pour une 2ème vie.

Nos équipes Recherche & Développement ont aussi un savoir-faire reconnu dans le développement et l’utilisation des bio-composites comme Flaxcomp®.

Osez le composite biosourcé 100% recyclable en associant la fibre de lin et une résine thermoplastique. Nous vous accompagnons sur le procédé de fabrication qui respecte la fibre, grâce à notre expertise Flaxcomp®.

Le parcours client chez DEMGY Atlantique

Schéma du parcours client

1. Analyse de la faisabilité industrielle : En réponse à vos cahiers des charges et exigences implicites, nous réalisons nos offres avec le meilleur compromis technico-économique.

2. Phase de développement : cette étape est certainement la plus importante au bon déploiement du projet. Du co-design jusqu’à la mise en production, nos équipes de développement mettent à votre disposition leur savoir-faire pour garantir la parfaite maîtrise de vos exigences.

3. Gestion de la supply chain : à présent, nous avons toutes les clés en main pour démarrer votre projet dans les meilleures conditions. Il est maintenant temps de se coordonner sur la gestion de l’ensemble de la supply chain pour votre production en grande série en France ou à l’international.

4. Production : Avec plus de 70 ans de savoir-faire sur la production en grande série, nos lignes de productions automatisées vous assurent une qualité irréprochable récompensée par de nombreuses certifications. (reprendre les certif citées dans la dernière partie du doc). De même, la digitalisation de nos ateliers, grâce à notre M.E.S (Manufacturing Execution System), amène un suivi en temps réel de nos productions.

Notre Atelier intégré d’outillage nous permet d’assurer la pleine maîtrise de la qualité de nos productions.

5. Management de la Qualité : Ce processus est entièrement digitalisé, ce qui nous permet d’accéder à l’historique de la pièce tout au long de sa vie.

Connaissez-vous nos domaines d'activité ? Découvrez-les!

Le domaine d’activité le plus demandeur est celui de l’Automobile. C’est notre marque de fabrique ! Nous produisons des boîtiers de clefs électroniques, des afficheurs multimédias, des boitiers de commande (BCM pour Body Control Module) pour les équipementiers de l’électronique automobile, mais aussi des raccords pour les lignes de carburation, des pièces décoratives d’intérieur d’habitacle, des collecteurs de circuit de refroidissement moteur, des pièces d’étanchéité sur tous les ouvrants, des supports moteur, des pièces de filtration ou encore des boîtiers de moteurs pour les toits ouvrants.

DEMGY Atlantique s’adresse également au secteur du Médical. Nous sommes certifiés ISO 13485, un gage de qualité pour vos pièces les plus exigeantes.

Nous produisons également des pièces pour les secteurs des Sports et Loisirs, de l’Aéronautique, ou encore de l’Electroménager. Notre polyvalence fait notre force : peu importe la nature de votre projet, nous sommes en mesure de le réaliser, de la conception à la livraison du produit fini !

Nos équipes vous accompagnent

Un chargé d’affaires et un chef de projet vous sont dédiés pour mener à bien vos projets ; ils coordonnent les actions du bureau d’études pour le co-design des pièces et l’étude des outillages avec le logiciel de CAD CATIA V5 et le logiciel de Rhéologie Moldflow®. Ils assurent la synergie avec toutes les équipes impliquées : qualité, industrialisation, essai et métrologie.

Chez DEMGY Atlantique, tous nos collaborateurs sont de véritables experts à votre service. Du début à la fin de votre projet, vous êtes accompagnés par des personnes motivées, passionnées et entièrement à votre service pour répondre au mieux à vos besoins.

DEMGY Atlantique, la qualité certifiée pour vos projets

DEMGY Atlantique tient compte de l’importance stratégique de la Qualité et se donne les moyens pour améliorer, sans cesse, cette dernière.

DEMGY Atlantique est titulaire de la certification IATF 16949, une véritable assurance de qualité appliquée aux domaines de l’automobile. Délivrée par l’International Automotive Task Force. De la conception à la production, cette certification est un gage de rigueur et de performance industrielle.

DEMGY Atlantique est titulaire de la certification IATF 16949, une véritable assurance de qualité appliquée aux domaines de l’automobile. Délivrée par l’International Automotive Task Force. De la conception à la production, cette certification est un gage de rigueur et de performance industrielle.

DEMGY Atlantique est également titulaire de la certification EN 9100, une norme européenne mondialement reconnue qui récompense la qualité des produits et des services pour les secteurs de l’aéronautique, de la défense et du spatial. Elle est décernée aux entreprises qui savent anticiper et minimiser les risques, atteindre des niveaux d’excellence en matière de rapidité et de fiabilité, toujours dans une optique d’amélioration continue.

DEMGY Atlantique est également titulaire de la certification EN 9100, une norme européenne mondialement reconnue qui récompense la qualité des produits et des services pour les secteurs de l’aéronautique, de la défense et du spatial. Elle est décernée aux entreprises qui savent anticiper et minimiser les risques, atteindre des niveaux d’excellence en matière de rapidité et de fiabilité, toujours dans une optique d’amélioration continue.

En ce qui concerne le secteur médical, DEMGY Atlantique bénéficie de la norme ISO 13485. Cette dernière atteste d’un bon management de la qualité lors de la fabrication des dispositifs médicaux.

En ce qui concerne le secteur médical, DEMGY Atlantique bénéficie de la norme ISO 13485. Cette dernière atteste d’un bon management de la qualité lors de la fabrication des dispositifs médicaux.

De même, nous nous engageons à limiter un maximum nos impacts environnementaux, dans une démarche de développement durable. L’obtention de la certification ISO 14001 est le reflet de notre engagement environnemental pour une industrie plus responsable.

De même, nous nous engageons à limiter un maximum nos impacts environnementaux, dans une démarche de développement durable. L’obtention de la certification ISO 14001 est le reflet de notre engagement environnemental pour une industrie plus responsable.